Comprehensive Guide to Engine Components for Heavy-Duty Trucks

Many aspects of heavy-duty truck performance, especially in European, UK, and Irish markets, depend on the quality and reliability of engine components. Using high-quality parts not only enhances durability but also improves fuel efficiency and overall truck performance. In this guide, you’ll explore how to choose the right engine parts, understand the role of turbochargers, maintain belts and hoses, and ensure compliance with regional regulations. Whether you’re managing a fleet or maintaining a single vehicle, this guide provides actionable insights to keep your heavy-duty trucks running smoothly and efficiently.

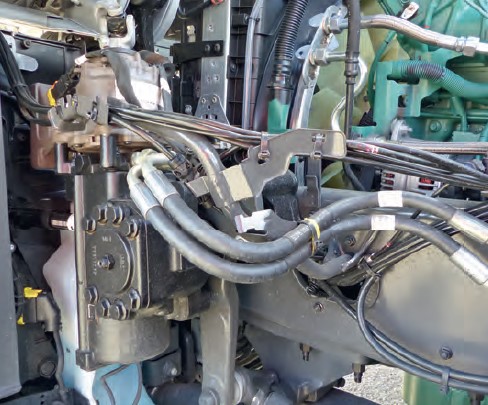

Key Engine Components for Heavy-Duty Trucks

Before plunging into the specifics of heavy-duty truck engines, it’s vital to understand the core components that keep your vehicle running efficiently. These parts not only ensure durability but also play a significant role in fuel efficiency and overall performance, especially in European, UK, and Irish markets. From the cylinder block to the crankshaft, each component has a unique function that contributes to the engine’s reliability under demanding conditions.

Cylinder Block and Head

Above all, the cylinder block and head form the foundation of your truck’s engine. The block houses the pistons and cylinders, while the head contains the valves and combustion chambers. Together, they ensure proper compression and combustion, which are vital for power generation. For European trucks, using high-quality materials in these components is key to meeting stringent emissions standards and ensuring long-term durability.

Pistons and Connecting Rods

Between the cylinder block and the crankshaft, pistons and connecting rods play a pivotal role in converting combustion energy into mechanical motion. Pistons move up and down within the cylinders, while connecting rods transfer this motion to the crankshaft. These components must withstand extreme pressure and heat, making material quality and precision engineering critical for heavy-duty applications.

For instance, pistons in European trucks are often made from lightweight yet durable alloys to enhance fuel efficiency and reduce wear. Connecting rods, on the other hand, are designed to handle high torque loads, ensuring smooth power delivery even under heavy loads. Regular inspection of these parts can prevent costly engine failures and downtime.

Crankshaft and Camshaft

Crankshaft and camshaft are the backbone of your engine’s motion system. The crankshaft converts the linear motion of the pistons into rotational energy, which powers your truck’s drivetrain. Meanwhile, the camshaft controls the opening and closing of the engine’s valves, ensuring precise timing for combustion. Both components must be robust and precisely balanced to handle the demands of heavy-duty operations.

Plus, modern crankshafts and camshafts are often crafted from high-strength steel or alloy, offering enhanced durability and performance. For trucks operating in Ireland and the UK, ensuring these components meet EU emissions standards is vital for compliance and optimal engine efficiency. Regular maintenance, including lubrication checks, can extend their lifespan and prevent unexpected breakdowns.

Fuel Systems in Heavy-Duty Engines

Clearly, the fuel system is the lifeline of your heavy-duty truck’s engine, ensuring optimal performance and fuel efficiency. In European, UK, and Irish markets, where stringent emissions standards like Euro 6 are enforced, a well-maintained fuel system is imperative. It not only enhances your truck’s power output but also reduces emissions, keeping your vehicle compliant with environmental regulations. From fuel injectors to turbochargers, each component plays a vital role in delivering the right fuel-air mixture for combustion, ensuring your truck operates smoothly under heavy loads and long-haul conditions.

Fuel Injectors

After the fuel pump delivers fuel to the engine, the fuel injectors take over by precisely spraying the right amount of fuel into the combustion chamber. This process is critical for maintaining fuel efficiency and reducing emissions, especially in European trucks where compliance with Euro 6 standards is mandatory. High-quality fuel injectors ensure consistent performance, prevent fuel wastage, and help your engine run cleaner and more efficiently. Regular inspection and timely replacement of worn injectors can save you from costly repairs and downtime.

Engine Components – Turbochargers and Superchargers

Fuel efficiency and power are significantly enhanced by turbochargers and superchargers, which force more air into the combustion chamber. Turbochargers, in particular, are widely used in European trucks due to their ability to improve fuel economy by up to 20% while boosting engine power. Superchargers, though less common, provide immediate power delivery, making them ideal for specific heavy-duty applications. Both systems help your truck meet strict EU emissions standards while handling heavy loads with ease.

To maximize the benefits of turbochargers and superchargers, you need to ensure proper maintenance. Regularly check for wear on turbine blades and monitor oil levels to prevent damage. Turbochargers, especially in long-haul trucks, should be inspected every 50,000–75,000 miles to maintain optimal performance. By keeping these components in top condition, you can extend the lifespan of your engine, reduce fuel consumption, and stay compliant with environmental regulations.

Cooling and Lubrication Systems

Not only do cooling and lubrication systems keep your heavy-duty truck’s engine running smoothly, but they also play a vital role in preventing overheating and reducing wear. Proper maintenance of these systems ensures your truck operates efficiently, especially in demanding conditions. For a deeper explore how these systems function, check out this Comprehensive Guide to Truck Parts and Their Functions.

Radiators and Coolant Pumps

The radiator and coolant pump work together to regulate your engine’s temperature, preventing overheating during long hauls. A well-maintained radiator ensures efficient heat dissipation, while the coolant pump circulates coolant to absorb and transfer heat. Regularly inspecting these components can save you from costly repairs and downtime.

Oil Pumps and Filters

Between the oil pump and filter, your engine’s lubrication system ensures all moving parts operate smoothly. The oil pump circulates oil to reduce friction, while the filter removes contaminants that could damage your engine. Keeping these components in top condition is imperative for maintaining engine longevity and performance.

Indeed, oil pumps and filters are the backbone of your engine’s lubrication system. Without proper oil circulation, your engine could suffer from increased friction, leading to premature wear and potential failure. Regularly replacing your oil filter and monitoring oil pressure can help you avoid these issues, ensuring your truck remains reliable on the road.

Exhaust Systems and Emissions Control

After combustion, your heavy-duty truck’s exhaust system plays a vital role in managing emissions and ensuring compliance with stringent EU and Irish regulations. Modern systems, such as Diesel Particulate Filters (DPF) and Selective Catalytic Reduction (SCR), are designed to reduce harmful pollutants like nitrogen oxides (NOx) and particulate matter. By maintaining these components, you not only meet environmental standards but also enhance your truck’s performance and fuel efficiency, making them important for long-haul operations in Europe, the UK, and Ireland.

Diesel Particulate Filters (DPF)

Diesel Particulate Filters are designed to capture and store soot from your truck’s exhaust, preventing it from being released into the atmosphere. Over time, the trapped soot is burned off during a process called regeneration, ensuring the filter remains effective. Regular maintenance of your DPF is important to avoid blockages, which can lead to reduced engine performance and increased fuel consumption. For trucks operating in Ireland and the UK, keeping your DPF in optimal condition is key to complying with Euro 6 emissions standards.

Selective Catalytic Reduction (SCR)

Diesel engines equipped with Selective Catalytic Reduction systems use a urea-based solution, commonly known as AdBlue, to convert harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. This technology is highly effective in reducing emissions, making it a cornerstone of modern heavy-duty trucks in Europe. By ensuring your SCR system is functioning correctly, you can achieve better fuel efficiency and meet the strict environmental regulations required for Irish and UK roads.

Considering the importance of SCR systems, it’s worth noting that they can reduce NOx emissions by up to 90%, making them indispensable for compliance with Euro 6 standards. Regular checks on your AdBlue levels and system components will help you avoid unexpected downtime and costly repairs. For trucks operating in Ireland, sourcing high-quality AdBlue and SCR-compatible parts from trusted suppliers ensures your vehicle remains efficient and environmentally friendly.

Electrical and Ignition Systems

All heavy-duty trucks rely on robust electrical and ignition systems to ensure smooth operation and optimal performance. These systems power crucial components like alternators, starters, glow plugs, and ignition coils, which are vital for starting your engine and maintaining its efficiency. For European, UK, and Irish markets, using high-quality parts ensures compliance with emissions standards and enhances fuel efficiency. Regular maintenance of these systems can prevent unexpected breakdowns and extend the lifespan of your truck, making it a worthwhile investment for long-haul operations.

Alternators and Starters

Beside the engine, alternators and starters are fundamental to your truck’s electrical system. The alternator keeps your battery charged and powers electrical components while the engine runs, while the starter motor initiates the engine’s operation. For European trucks like Scania or Volvo, choosing OEM or high-quality aftermarket alternators and starters ensures reliability and durability. Regular checks on these components can help you avoid electrical failures, especially during long journeys across Ireland or the UK.

Glow Plugs and Ignition Coils

To ensure your diesel engine starts efficiently, especially in colder climates, glow plugs and ignition coils play a key role. Glow plugs preheat the combustion chamber, making it easier to ignite the fuel, while ignition coils deliver the necessary voltage to spark plugs in petrol engines. For trucks operating in Ireland’s variable weather, maintaining these components is crucial for consistent performance and reduced emissions.

And when it comes to glow plugs and ignition coils, their condition directly impacts your truck’s fuel efficiency and emissions compliance. Worn-out glow plugs can lead to hard starts and increased fuel consumption, while faulty ignition coils may cause misfires. Regularly inspecting and replacing these parts, particularly in European trucks, ensures your vehicle meets Euro 6 standards and operates at peak efficiency.

Engine Components Maintenance Tips for Longevity

Your heavy-duty truck’s engine components require consistent care to ensure long-term performance. Start by following these steps:

- Regularly check oil and coolant levels to prevent overheating and wear.

- Inspect belts and hoses for cracks or leaks to avoid unexpected breakdowns.

- Monitor the turbocharger for signs of wear, such as reduced power or unusual noises.

Any neglect can lead to costly repairs, so prioritize routine maintenance. For a deeper look into engine care, explore Understanding Diesel Engine Components to enhance your knowledge.

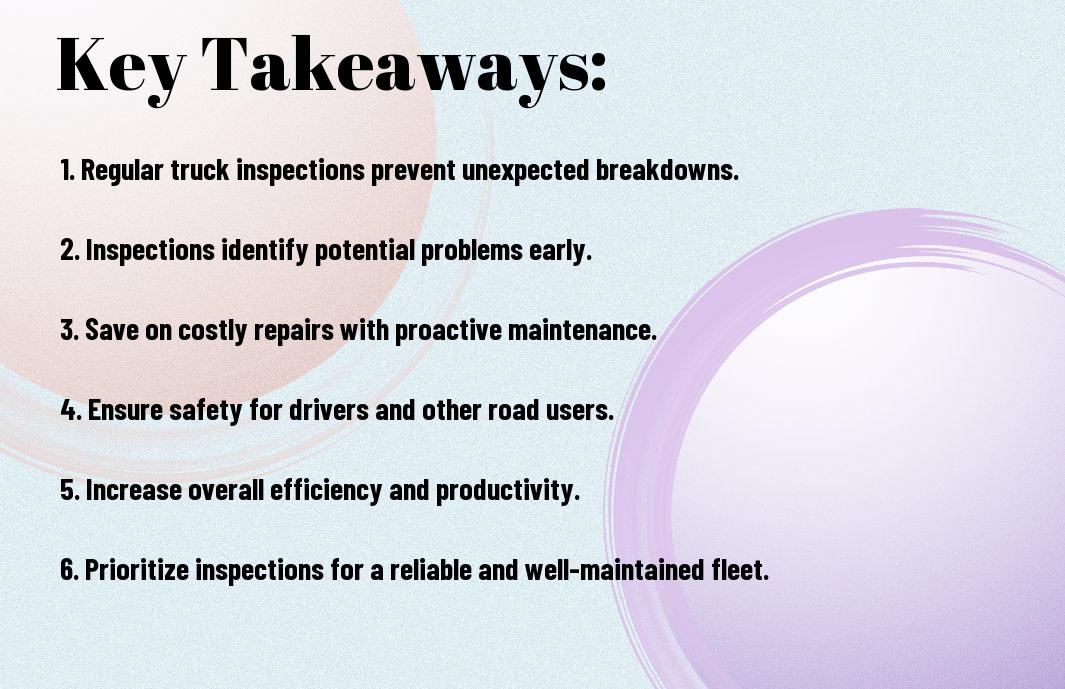

Regular Inspection Schedules

Around every 10,000 miles, schedule a thorough inspection of your truck’s engine components. Focus on checking the timing belt, coolant hoses, and turbocharger for wear. Adhering to manufacturer-recommended intervals ensures your engine runs efficiently and reduces the risk of unexpected failures. Consistent inspections also help you identify minor issues before they escalate into major problems.

Common Issues and Troubleshooting

Against the demands of heavy-duty use, your truck’s engine may face issues like oil leaks, turbocharger failure, or belt wear. Early detection is key—listen for unusual noises, monitor performance drops, and check for visible leaks. Addressing these problems promptly can save you from costly repairs and downtime.

Schedules for troubleshooting should align with your regular maintenance routine. For example, if you notice reduced fuel efficiency or power, inspect the turbocharger and fuel injectors. Keeping detailed records of inspections and repairs helps you track patterns and plan preventative measures effectively.

Summing Up Engine Components

Ultimately, understanding your heavy-duty truck’s engine components ensures optimal performance, fuel efficiency, and compliance with European and Irish regulations. By selecting high-quality parts, prioritizing regular maintenance, and considering upgrades tailored to your needs, you can extend your truck’s lifespan and minimise downtime. Whether you’re managing a fleet or maintaining a single vehicle, staying informed about engine components empowers you to make smarter decisions.

For reliable parts and expert guidance,

visit odonnellcommercials.ie or

Call 074 93 90122 to keep your trucks running at peak performance.